칩 저항기

LIGHBIG은 Hokuriku Electric industy (일본) 국내 단독 대리점으로서 강력한 내구성 및 신뢰성을 바탕으로 정밀 저항기를 취급하고 있습니다.

고품질의 소재를 사용하며, 열에 대한 안정성 및 전력 전자, 통신, 자동차, 산업기계 등 다양한 분야에 적용할 수 있습니다.

고품질의 소재를 사용하며, 열에 대한 안정성 및 전력 전자, 통신, 자동차, 산업기계 등 다양한 분야에 적용할 수 있습니다.

OUR SERVICE

-

신속한 대응LIGHBIG은 고객의 요구사항을 빠르게 파악하고 신속하게 대응합니다.

-

우수한 기술 지원숙련된 기술 전문가들이 고객을 직접 방문하여 기술 지원 및 문제 해결을 돕고 있습니다.

-

맞춤형 솔루션고객의 특성과 사업 환경을 깊이 있게 이해하여 고객 맞춤형 솔루션을 제공하고 있습니다.

-

지속적 관리지속적으로 고객을 관리하여 고객 만족도를 높이고 있습니다.

| *1 Model No. |

CR04 (CR1/32) |

CR06 (CR1/20) |

CR10 (CR1/168) |

CR16 (CR1/16) |

CR20 (CR1/10) |

CR32 (CR1/8) |

CR35 (CR1/4) |

CR50 (CR1/2) |

CR64 (CR1) |

| Size Code (inch) | 01005 | 0201 | 0402 | 0603 | 0805 | 1206 | 1210 | 2010 | 2512 |

| Size Code (mm) | 0402 | 0603 | 1005 | 1608 | 2012 | 3216 | 3225 | 5025 | 6432 |

*1() : Conventional Model No.

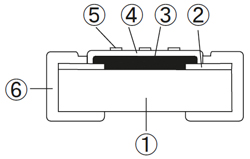

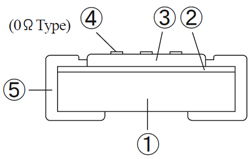

■ Construction

-

Symbol Material List ① Alumina substrate ② Conductor ③ Resistive film ④ Over coat ⑤ Marking *2 ⑥ Side termination -

Symbol Material List ① Alumina substrate ② Conductor ③ Over coat ④ Marking *2 ⑤ Side termination *2 No marking on CR04, CR06, CR10, CR16 (E-96 Series)

■ Model Designation

-

-

CR1/16①

-

102②

-

J③

-

V④

Conventional Model No.

-

-

-

CR1/16①

-

102②

-

J③

-

V④

Model No.

-

-

-

CR1/16①

-

102②

-

J③

-

V④

-

G⑤

Model No. for user who requires it.

-

-

① Model No. CR04 (CR1/32) CR06 (CR1/20) CR10 (CR1/16S) CR16 (CR1/16) CR20 (CR1/10) CR32 (CR1/8) CR35 (CR1/4) CR50 (CR1/2) CR64 (CR 1) -

② Resistance 3 or 4 digit Resistance Marking 0 Ω → 000 4.7 Ω → 4R7 1k Ω → 102 1.02k Ω → 1021 -

③ Tolerance (%) Symbol Tolerance D ±0.5 F ±1.0 G ±2.0 J ±5.0 K ±10.0 0Ω type is no marking -

④ Packaging Symbol Packaging B Bulk V Paper taping E Embossed taping -

⑤ TCR Symbol TCR(ppm/°C) G ±50 H ±100 K ±250 M ±500

■ Rating

| *1 Model No. |

Rated Wattage (W) | Tolerance (%) | Resistance (Ω) | T.C.R. (ppm /°C) | Max. Working Voltage (V) |

Max. Overload Voltage (V) |

0Ω Type | ||

| Rated Curent (A) |

Resistance (Ω) | ||||||||

| CR04 | 0.03 | F | ±1 | 10~1M | ±250 | 15 | 30 | 0.3 | Max. 50m Ω |

| G | ±2 | 10~1M | ±250 | ||||||

| J | ±5 | 10~1M | ±250 | ||||||

| CR06 (CR1/20) | 0.05 | F | ±1 | 10~1M | ±200 | 25 | 50 | 0.5 | |

| G | ±2 | 10~1M | ±200 | ||||||

| J | ±5 | 1.0~9.1 | ±400 | ||||||

| J | ±5 | 10~10M | ±200 | ||||||

| CR10 (CR1/16S) | *2 0.10 |

D | ±0.5 | 10~97.6 | ±100 | 50 | 100 | 1.0 | |

| D | ±0.5 | 100~1M | ±50 | ||||||

| F | ±1 | 10~1M | ±100 | ||||||

| G | ±2 | 10~1M | ±200 | ||||||

| J | ±5 | 1.0~9.1 | ±300 | ||||||

| J | ±5 | 10~10M | ±200 | ||||||

| CR16 (CR1/16) | 0.125 | D | ±0.5 | 100~976 | ±100 | 50 | 100 | 1.0 | |

| D | ±0.5 | 1K~100K | ±50 | ||||||

| F | ±1 | 10~1M | ±100 | ||||||

| G | ±2 | 10~1M | ±200 | ||||||

| J | ±5 | 1~4.3 | -100~+600 | ||||||

| J | ±5 | 4.7~3.3M | ±200 | ||||||

| J | ±5 | 3.6M~10M | ±300 | ||||||

| CR20 (CR1/10) | 0.25 | D | ±0.5 | 100~1K | ±100 | 150 | 200 | 1.5 | |

| F | ±1 | 10~1K | ±100 | ||||||

| G | ±2 | 10~1K | ±200 | ||||||

| J | ±5 | 1~4.3 | -100~+600 | ||||||

| J | ±5 | 4.7~1K | ±200 | ||||||

| *2 0.25 |

D | ±0.5 | 1.02K~100K | ±100 | |||||

| F | ±1 | 1.02K~1M | ±100 | ||||||

| G | ±2 | 1.1K~1M | ±200 | ||||||

| J | ±5 | 1.1K~3.3M | ±200 | ||||||

| J | ±5 | 3.6M~10M | ±300 | ||||||

| K | ±10 | 11M~22M | ±300 | ||||||

| CR32 (CR1/8) | 0.25 | D | ±0.5 | 100~100K | ±100 | 200 | 400 | 2.0 | |

| F | ±1 | 10~1M | ±100 | ||||||

| G | ±2 | 10~1M | ±200 | ||||||

| J | ±5 | 1~4.3 | -100~+600 | ||||||

| J | ±5 | 4.7~3.3M | ±200 | ||||||

| J | ±5 | 3.6M~10M | ±300 | ||||||

| K | ±10 | 11M~22M | ±300 | ||||||

| CR35 (CR1/4) | 0.50 | D | ±0.5 | 100~100K | ±100 | 200 | 400 | 2.0 | |

| F | ±1 | 10~1M | ±100 | ||||||

| G | ±2 | 10~1M | ±200 | ||||||

| J | ±5 | 1~4.3 | -100~+600 | ||||||

| J | ±5 | 4.7~3.3M | ±200 | ||||||

| J | ±5 | 3.6M~10M | ±300 | ||||||

| CR50 (CR1/2) | 0.75 | F | ±1 | 10~1M | ±200 | 200 | 400 | 2.0 | |

| G | ±2 | 10~1M | ±300 | ||||||

| J | ±5 | 1.0~9.1 | ±500 | ||||||

| J | ±5 | 10~1M | ±300 | ||||||

| CR64 (CR1) | 1.00 | J | ±5 | 1.0~9.1 | ±500 | 200 | 400 | 2.0 | |

| J | ±5 | 10~1M | ±300 | ||||||

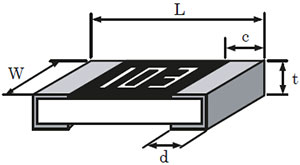

■ Dimension

-

Model No. *1 L W c d t CR04 (CR1/32) 0.40 ± 0.02 0.20 ± 0.02 0.10 ± 0.03 0.10 ± 0.03 0.13 ± 0.02 CR06 (CR1/20) 0.60 ± 0.03 0.30 ± 0.03 0.12 ± 0.05 0.15 ± 0.05 0.23 ± 0.03 CR10 (CR1/16S) 1.00 ± 0.05 0.50 ± 0.05 0.20 ± 0.10 0.25 ± 0.10 0.35 ± 0.05 CR16 (CR1/16) 1.60 ± 0.15 0.80 + 0.20 0.25 ± 0.20 0.25 ± 0.20 0.45 ± 0.10 - 0.10 CR20 (CR1/10) 2.00 + 0.20 1.25 + 0.20 0.40 ± 0.20 0.40 ± 0.20 0.50 ± 0.10 - 0.10 - 0.10 CR32 (CR1/8) 3.20 + 0.10 1.60 + 0.10 0.50 ± 0.20 0.50 ± 0.20 0.55 + 0.15 - 0.15 - 0.15 - 0.05 CR35 (CR1/4) 3.20 + 0.10 2.60 + 0.10 0.50 ± 0.20 0.50 ± 0.20 0.55 + 0.15 - 0.15 - 0.15 - 0.05 CR50 (CR1/2) 5.00 ± 01. 5 2.50 ± 0.20 0.60 ± 0.25 0.60 ± 0.25 0.56 ± 0.15 CR64 (CR1) 6.30 ± 0.15 3.20 ± 0.20 0.60 ± 0.25 0.60 ± 0.25 0.56 ± 0.15

-

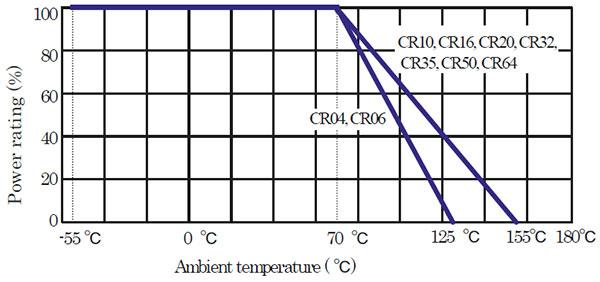

■ Power rating

For resistors operated in ambient temperature above 70 °C, power rating must be derated in accordance with the derating curve.

Operating temperature range CR10~CR64:-55 +155°C

CR04, CR06: -55 +125°C■ Packaging

Refer "Dimesion, Packaging,etc."