Secondary Bettery

LIGHBIG collaborates with Mesnac to provide secondary battery equipment and solutions.

By applying advanced technology, we offer efficient and reliable battery production equipment.

We also provide customized solutions, as well as after-sales support and maintenance services to ensure the stable operation of our products.

By applying advanced technology, we offer efficient and reliable battery production equipment.

We also provide customized solutions, as well as after-sales support and maintenance services to ensure the stable operation of our products.

■ Product M/C

■ Measuring equipent

-

-

Optical Microscope for Burr MeasurementOptical microscope capable of measuring micron-level electrode cut surface burrsModel : 300CNC

Magnification : Max 1570.48x

XY axis travel range : 300*200*200

Accuracy : 2.0+L/200um

Resolution : 0.001mm

Optional part : Coaxial light lens and 10X metallographic lens

-

-

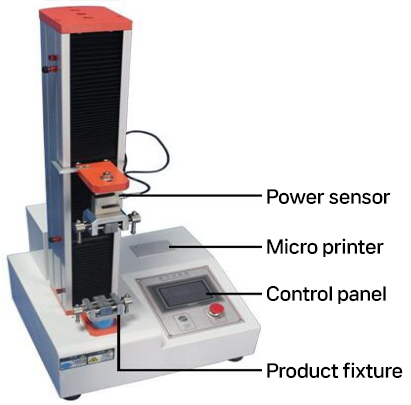

Tensile Strength TesterMeasurement of adhesive strength of welding Spot and bonding strength of Active Material and Current Collector.Capacity : 50KG(303-50), 100KG(303-100), 200KG(303-200)

Unit conversion : KGF/N/LBF

Resolution : 1/10000

Power precision : <±0.5%

Test speed : 0-300mm/min

Test space : 600MM (without the jig)

Test width : Around 120mm

■ Materials

-

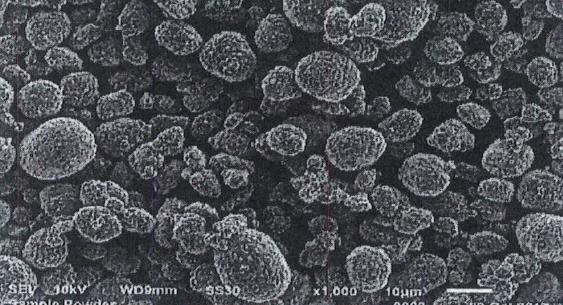

NCM : Secondary Battery Anode Material

NCM523, 622, 811, High Nickel, etc.

NCM523, 622, 811, High Nickel, etc.

-

Ni+Co+Mn wt% 59.00±3.00 58.68 Li wt% 7.40±0.20 7.26 Fe wt% ≤0.0050 0.0008 Cu wt% ≤0.0030 0.0000 Ca wt% ≤0.0100 0.0022 Na wt% ≤0.0500 0.0144 Zn wt% ≤0.0020 0.0000 pH - 11.6±0.20 11.55 H2O wt% ≤0.0400 0.0082

-

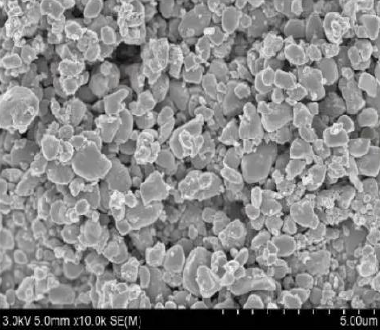

LFP : Secondary Battery Anode Material

-

C wt% 1.10±0.30 Li wt% 4.40±0.20 Fe wt% 33.50±1.50 P wt% 19.50±1.50 pH - 9.80±1.00 Moisture content ppm ≤1000 Ni+Cr+Cu+Zn ppm ≤250 Na+K ppm ≤400

-

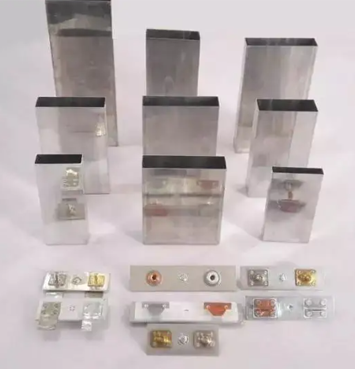

Prismatic Can

Square Can using the latest transfer mold.

Square Can using the latest transfer mold.

-

Cylindrical Can

Cylindrical Cans using the latest Transfer mold.

Cylindrical Cans using the latest Transfer mold.

18650, 21700, 4680, 46100, etc.

■ New Technology

ALTP: Electrolyte for All-Solid and Semi-Solid State battery

-

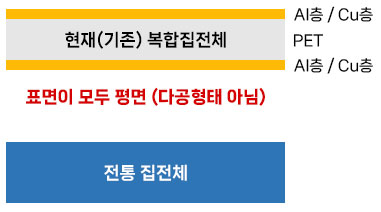

Problems with Current Composite Current Collector

Flat surface of the collector: poor adhesion to the electrodes

Sandwich structure makes multi-layer welding impossible

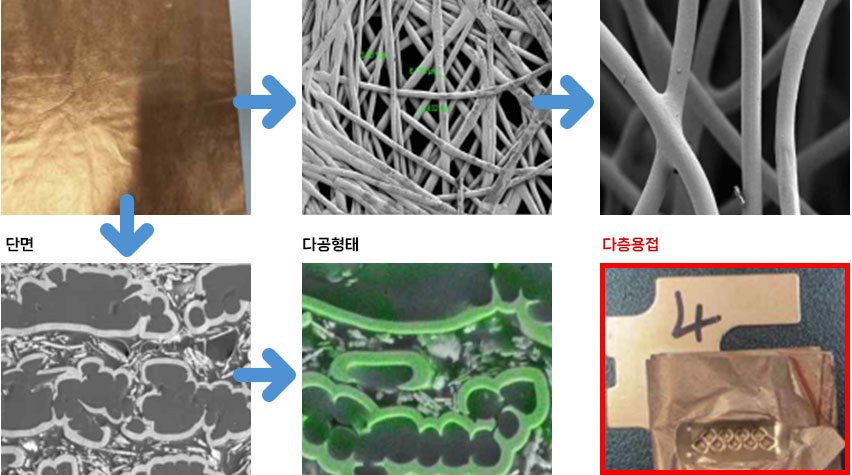

New Generation of Composite Current Collector

Porous structure: excellent adhesion to electrodesAll porous parts are metallized: multi-layer welding possible

Dry Electrode Production Equipment: for laboratory use

-

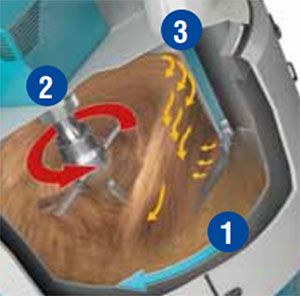

High Speed Tilted MIXING

Function: Rotates at a maximum speed of 6000 RPM, creates a three-dimensional space with the individual rotation of the high-speed rotating body and the mixer barrel, and the scraper function that pushes the powder on the wall to the center, and generates shear stress in a direction perpendicular to the rotation direction, resulting in fiberization and elongation

Advantage: Favorable for fast and uniform mixing, no need for separate cyclone and fiberization equipment.

The angle of the rotating barrel can be reduced, and usually wet mixing is horizontal, and dry mixing is tilted at an angle, and dry and wet mixing are possible.

-

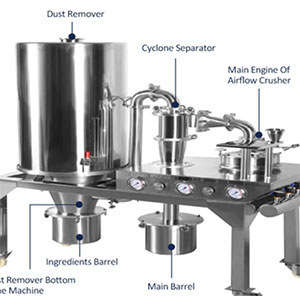

Ultrasonic MIXING

Function: Mixes powder with high-pressure air using ultrasonic waves, and is effective in crushing powder due to the characteristics of ultrasonic waves.

A cyclone can separate powders of a certain weight.

Advantage: Effectively separates lumped powders with ultrasonic waves, and fiberization occurs through the application of high-pressure force, and no separate fiberization equipment is required.